Advanced SWD Automation and Water Logistics

In the dynamic oil and gas industry, managing the voluminous byproduct of water—often ranging from three to ten barrels for every barrel of oil—poses significant economic and environmental challenges. Saltwater Disposal (SWD) efficiency and water management are not merely operational concerns but are pivotal in defining the sustainability and profitability of oilfield operations. Plow Technologies emerges as a leader in this arena, offering unparalleled SWD Automation and Alarm systems designed to optimize site efficiency and enhance safety, powered by our cutting-edge OnPing software-as-a-service.

Plow’s Distinctive Approach to SWD Automation

What distinguishes Plow Technologies in the field of automation is our commitment to delivering tailor-made solutions that cater specifically to the requirements of saltwater disposal facilities and reclamation sites. Our custom-built SWD packages integrate advanced sensors, meters, valve motors, and drives, ensuring your disposal or reclamation operation is not just automated but optimized for peak performance. Through automated trucker login, ticketing, and invoicing capabilities, Plow’s solutions simplify the process of integrating new companies and truckers, all while being backed by the innovative capabilities of our OnPing platform.

Elevating Operations with Full-Scale Automation

Plow Technologies is at the vanguard of introducing fully automated remote disposal sites, a game-changing service that sets new standards in the SWD sector. This innovative approach leverages the power of OnPing software alongside sophisticated kiosk systems, allowing for unprecedented levels of operational autonomy. Operators can now manage their facilities remotely, with the confidence that every aspect of the disposal process—from trucker check-ins to water handling and invoicing—is handled with precision and reliability. This leap towards full-scale automation represents our commitment to advancing technology that not only enhances operational efficiency but also supports the broader goals of environmental sustainability and regulatory compliance.

What We Offer

Continuous Monitoring and Supervisory Control: Our systems deliver 24/7 access to critical real-time data on pressure, tank levels, volumes, flow rates, and more, all customizable for your specific needs. With Plow, remote supervisory control over pumps and operations is not just a feature—it’s a standard.

Rapid Response and Downtime Reduction: With automated alerts for tank overflows, pump failures, and pipeline leaks, Plow’s SCADA systems enable you to act swiftly, preventing costly downtime and operational disruptions.

Enhanced Risk Mitigation: The environmental and financial stakes of SWD leaks and spills are high. Plow’s advanced monitoring and control systems serve as a critical line of defense, safeguarding against potentially catastrophic consequences.

Custom Data Reporting: Our solutions provide detailed data accumulation and reporting capabilities, making it easier to manage accounting and regulatory reporting requirements, with data segmentation available by truck, company, site, or region.

Related Content

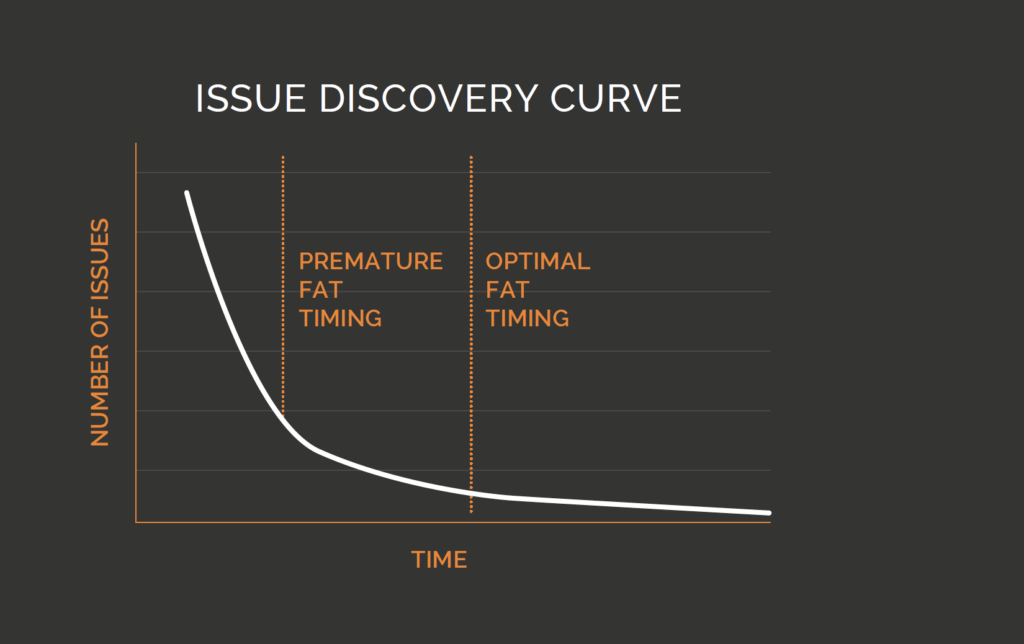

Ensuring Success: The Crucial Elements of FAT Testing in PLC Control Panels

The development of an automation project is a multidimensional endeavor, and Factory Acceptance Testing (FAT) emerges as the linchpin in ensuring its success.

As we navigate the complexities of industrial automation, the role of FAT testing becomes increasingly evident. It is a process that transcends the physicality of control panels, delving into the realms of sequence logic, visual representations, and meticulous specifications. These considerations form the bare minimum requirements, and their meticulous collection prior to project engagement becomes the harbinger of efficiency and success.

Building an Automation Business

Venturing into the realm of entrepreneurship as a PLC professional carries with it a mixture of...

Lets Talk

In an era where efficiency, sustainability, and safety are more critical than ever, partnering with Plow Technologies offers a clear path forward. Our comprehensive suite of SWD Automation solutions, coupled with our expertise in water management, sets a new standard for operational excellence in the oil and gas industry. We invite you to join us in this transformative journey. Let’s explore how our cutting-edge technologies and customized solutions can revolutionize your water management strategies, together paving the way for a more sustainable and profitable future.

Discover the power of automation and innovation with Plow Technologies. Reach out today to start a conversation about how we can elevate your operations to new heights.